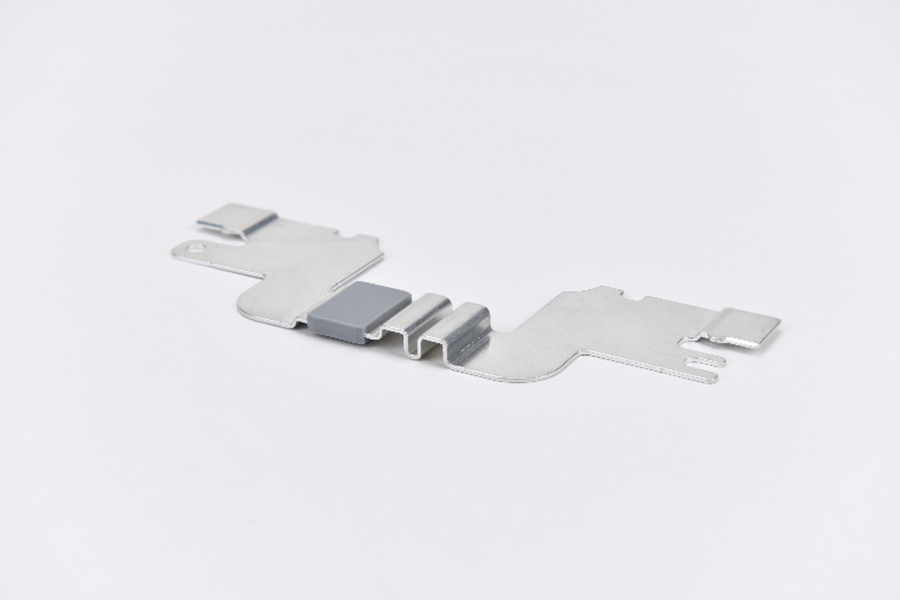

Customized New Energy Electric Vehicle Fuse Plastic Parts

Customized New Energy Electric Vehicle Fuse Plastic Parts

This customized new energy electric vehicle fuse plastic accessory is designed for new energy electric vehicle fuse application. The production process is carried out in the liquid silicone production workshop, which is equipped with advanced liquid silicone molding machines and control systems to ensure the accurate production and stable performance of the product. Fully automated robotic production methods can significantly improve production efficiency, while ensuring product quality stability and consistency.

During the production process, the product needs to be embedded in hardware and undergo 100% secondary vulcanization. The secondary vulcanization can further improve the mechanical properties and durability of the product, ensuring that the fuse maintains stable performance during long-term use. At the same time, in order to meet specific electrical performance requirements, the product needs to meet the requirements of the dyne value. The dyne value is an important indicator of the electrical resistance of insulating materials, and we ensure that our products meet the strict dyne value standards through precise process control and material selection.

The aluminum parts used in the molds are carefully selected and machined to provide good durability and precision. In order to facilitate traceability and management, the aluminum parts on the molds also adopt laser engraved QR code technology. By scanning the QR code, you can quickly access the product's production information, batch number and other data, which helps improve production efficiency and product quality.

With its advantages of high quality, efficient production and accurate inspection, this customized new energy electric vehicle fuse plastic part will become an ideal choice in the field of new energy electric vehicles. It will not only meet the diversified needs of customers, but also provide strong support for the development of the new energy electric vehicle industry.