Core Competiveness

- Digitalized Intelligent Manufacturing Platform

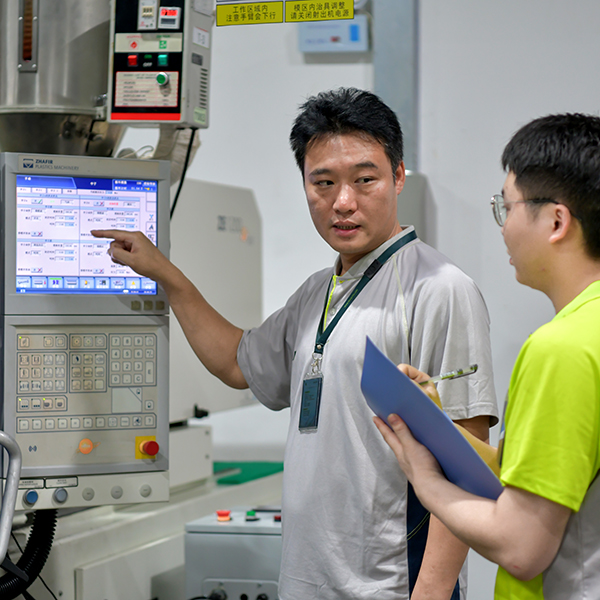

High Performance Mold Intelligent Manufacturing

Hongrita's mold manufacturing technology offers a range of advantages that contribute to its excellence in the industry:

- Precision and complexity

- Smart manufacturing

- High-quality

- Multi-cavitation molds

- Advanced tooling solutions

- Experienced engineering team

- Earlier supplier involvement

In conclusion, Hongrita's mold manufacturing technology offers advantages in terms of precision and complexity, smart manufacturing practices, high-quality mold production, multi-cavity mold capabilities, advanced tooling solutions, an experienced engineering team, and early supplier involvement. These advantages position Hongrita as a trusted mold manufacturing partner, capable of delivering high-performance molds that cater to a diverse range of industries and applications.

Precision Injection Molding Workshop

High-Quality Product Manufacturing

High-Quality Product Manufacturing: The precision injection molding workshop offers a more precise and stringent production environment, ensuring products meet high standards in terms of dimensions, appearance, and performance. This contributes to the production of high-quality.

Innovative Materials and Processes

Innovative Materials and Processes: The precision injection molding workshop enables more complex and refined injection manufacturing, providing Hongrita with opportunities to explore new materials and processes. This aids in continuous innovation and product performance enhancement.

Customized Production

Customized Production: The precision injection molding workshop allows for a higher level of personalized customization to meet diverse customer demands. Hongrita's customization capability provides a competitive advantage in addressing specific market needs.

Production Effciency Enhancememt

Production Effciency Enhancememt: The precision injetion molding workshop's fine manufacturing and advanced equipment can improve production efficiency, reduce production cycles, and provide faster delivery times. This caters to customers's urgent requirements.

Quality Monitoring and Improvements

Quality Monitoring and Improvements: The precision injection molding workshop facilitates easier monitoring of quality issues during production and enables timely improvements. This reduces defect rates,enhances product consistency,and stability.

/